03 Jan The expected shift from mass production to mass customization:

The expected shift from mass production to mass customization:

The present manufacturing world was shaped for many years by mass production. The purpose of factories was to make vast quantities of identical goods as cheaply and efficiently as possible. This strategy assisted businesses in reducing expenses, enhancing consistency, and satisfying rising international demand. Although mass production made goods more accessible and affordable, it did not allow for much customer choice or originality.

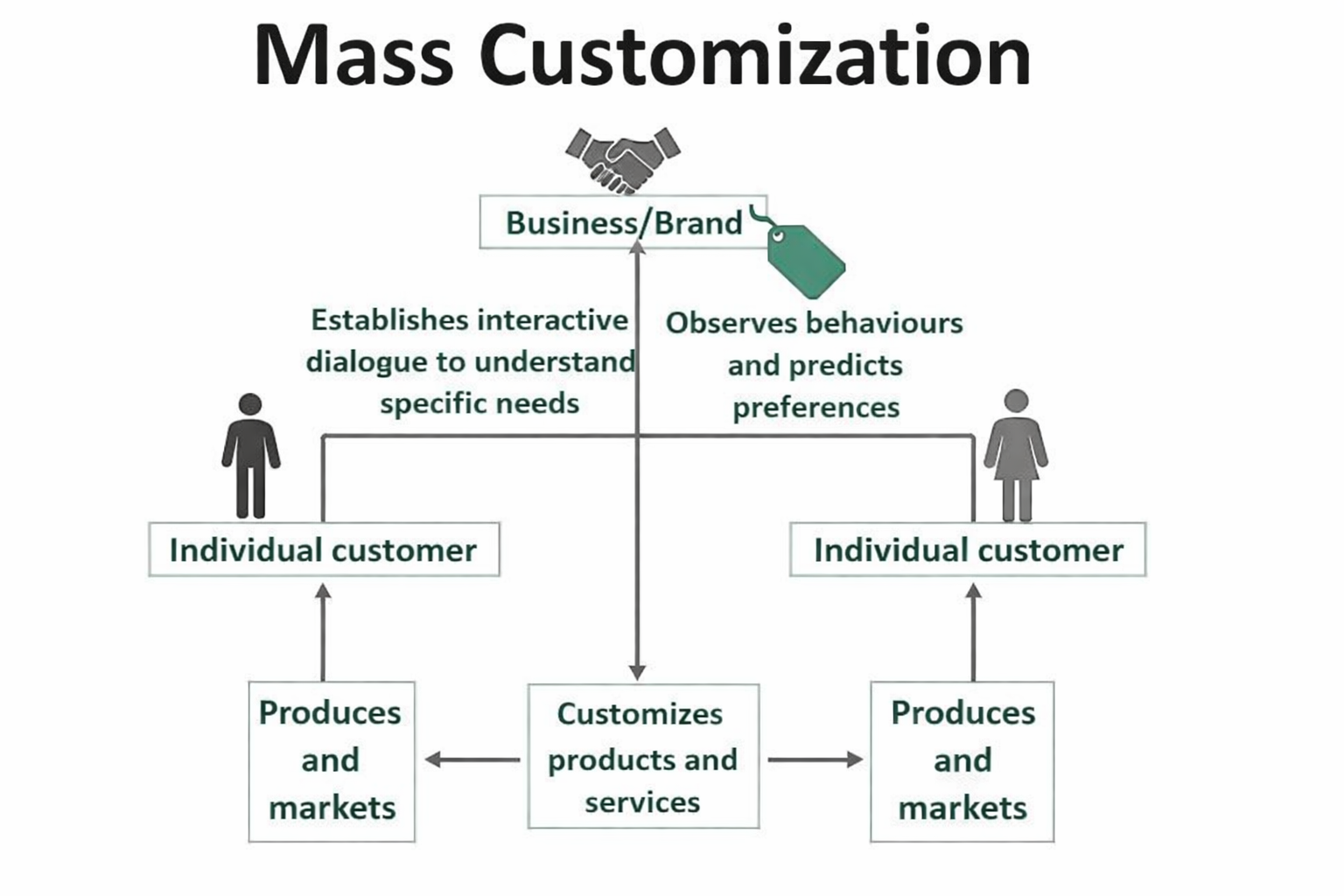

Consumer expectations are shifting as marketplaces change. Customers of today desire goods that suit their lifestyles, functional requirements, and personal preferences. A slow but significant transition from mass production to mass customization has resulted from this rising demand. Manufacturers are now concentrating on providing individualized solutions while preserving the efficiency of large-scale production, rather than providing a single standard product to everyone.

Customers can choose particular elements like style, size, color, functionality, or performance options thanks to mass customisation. The production process then incorporates these decisions immediately. Modern mass customisation is quick, adaptable, and economical in contrast to previous customization, which was costly and time-consuming. Advanced manufacturing technologies including CNC machining, robots, automation systems, artificial intelligence, and digital production planning enable this.

In this shift, flexible production methods are crucial. Production lines are no longer inflexible; they can swiftly adjust to many product variations with little setup time. Accuracy and efficiency are maintained throughout the process thanks to connected machinery, smart software, and real-time data. Because of this, businesses are able to create personalized goods at costs close to those of mass production.

Customers and businesses may both clearly benefit from the trend toward mass customization. Consumers are more satisfied and have more brand loyalty when they acquire goods that better meet their demands. This strategy gives producers a competitive edge in a crowded industry, opens up new market prospects, cuts waste, and enhances inventory management.

The transition from mass production to mass customisation is essentially a step toward manufacturing that is focused on the needs of the client. It allows businesses to react swiftly to shifting market needs by striking a balance between efficiency and customisation. Mass customisation is expected to become the norm for contemporary manufacturing as technology develops, creating a more adaptable and responsive industrial future.

Mass customization blends the best of two worlds:

✔ Efficiency of mass production

✔ Personalization of bespoke products

Where traditional manufacturing asked “How do we make one product for millions?” mass customization asks, “How do we make millions of unique products efficiently?” This shift is powered by digital technologies like 3D printing, flexible robotics, AI-driven design, and smart supply chains.

For customers, it means more choice and greater satisfaction. Imagine shoes tailored to your exact foot shape, furniture that fits your room dimensions AND style preferences, or software that adapts to how you like to work. That’s not the future — it’s happening now.

For businesses, the shift opens new opportunities. Personalization builds deeper customer loyalty and allows brands to charge premium prices. Data insights from customized orders help companies anticipate trends and make better decisions. And in an era where consumers value uniqueness and self-expression, customization is a powerful differentiator.

This transition impacts every industry — from automotive and fashion to consumer electronics and food services. Companies that embrace customization are not just meeting customer expectations — they’re redefining them.

No Comments