Gantry Machine Tending Robots

Why Choose Gantry MTR?

- Rapid Load/Unload Time: Quick unload → load time of just 10 seconds, maximizing operational efficiency.

- Multi-Machine Feeding Capability: Can feed up to four machines in a row, supporting either identical or different operations with multiple orientations, significantly reducing initial setup costs.

- Robust and Rigid Design: Engineered for maximum rigidity to ensure durability and stable performance.

- Space-Efficient Gantry Layout: Gantry pillars positioned adjacent to the CNC boundary, eliminating the need for extra floor space and reducing facility costs.

- Double Gripper with Positive Grip: Features a double gripper design that ensures enhanced part handling through secure and reliable gripping.

- Optional Integrated Auto Gauging System: Includes wear offset compensation to eliminate the need for operator intervention, enhancing accuracy and reducing downtime.

- Versatile Input and Output Mechanisms

-

- Input Options: Tray, gravity hopper, index conveyor, rotating stacker, and more.

-

- Output Options: Tray, index conveyor, belt conveyor, stacker, etc.

- User Friendly Control Interface: Equipped with intuitive 7” or 10” touchscreen HMIs for easy and efficient gantry operation & control.

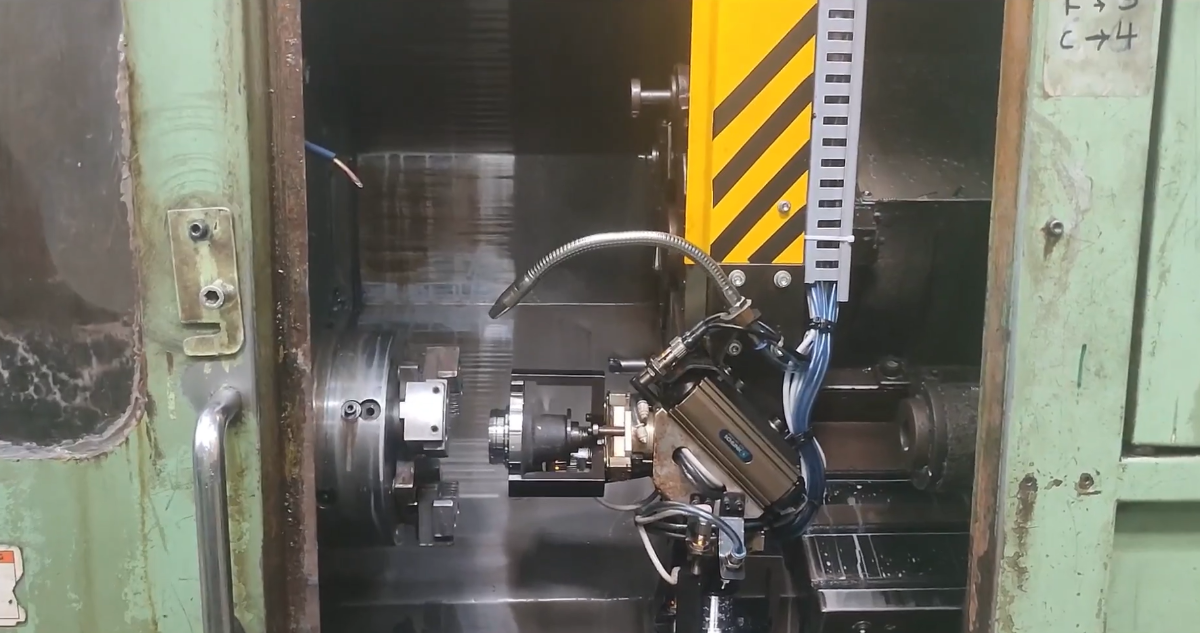

Gantry Based Machine Tending Robot

Common features

- Rapid speeds upto 2m/s

- Payload upto 5Kgs.

- Low floor space footprint

- Load Unload Cycle times of 12-14 seconds

- Can cater to 1-4 machines in a line

- Can take care of Oriented Loading

- Auto inspection and correction can be incorporated

- Can cater to twin spindle machines also effectively

What we offer:

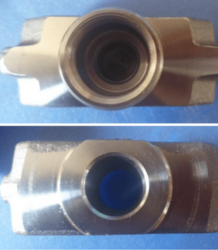

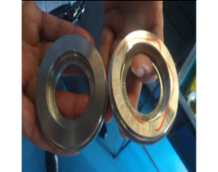

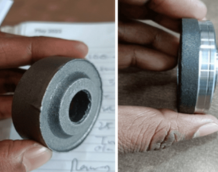

- Customer Approved Part Handling: Proven and reliable methods for handling both raw and finished parts, tailored to meet customer requirements.

- Automated Lubrication System: Ensures consistent and optimal lubrication for smooth and maintenance-free operation.

- Seamless CNC Integration: Advanced controls integration with the CNC machine, featuring standard safety interlocks for enhanced operational security. Integration support for FANUC and SIEMENS controllers.

- Comprehensive Installation and Commissioning: Expert installation and commissioning services to ensure smooth startup and optimal performance.

- Dedicated After-Sales Support: Responsive after-sales service, including on-site support, to maximize uptime and ensure customer satisfaction.

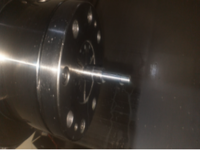

Prismatic Parts family

Discs

Shafts, Stepped shafts, Long shafts

Hollow parts

ROI & PAYBACK: Gantry Machine Tending Robot

Return on investment and Payback in (GMTR) Gantry machine tending robot Less than 3 years:

The GMTR (Gantry Machine Tending Robot) offers a fast return on investment, typically achieving full payback in less than 3 years. This is driven by reduced labour costs, increased machine uptime, consistent production quality, and improved operational efficiency—making it a cost-effective automation solution for long-term gains.

Benefits of Automation in GMTR – Gantry Machine Tending Robot

✅ High-Speed, High-Volume Handling

GMTRs are designed for rapid part transfer across multiple machines, ideal for high-volume, repetitive operations.

✅ Optimized Machine Utilization

Continuous and precise part loading/unloading minimizes idle time, ensuring machines run at maximum efficiency.

✅ Reduced Human Intervention

Gantry robots reduce the need for manual labor in repetitive and machining areas, freeing up manpower for skilled tasks.

✅ Precision and Repeatability

Engineered for accuracy, GMTRs maintain consistent cycle times and part positioning, improving product quality.

✅ Cost Savings Over Time

Automation reduces labor costs, energy consumption during idle times, and errors—leading to a lower cost per part.