23 Aug 5 Emerging Trends in Robotic Automation to Watch in 2025

5 Emerging Trends in Robotic Automation to Watch in 2025

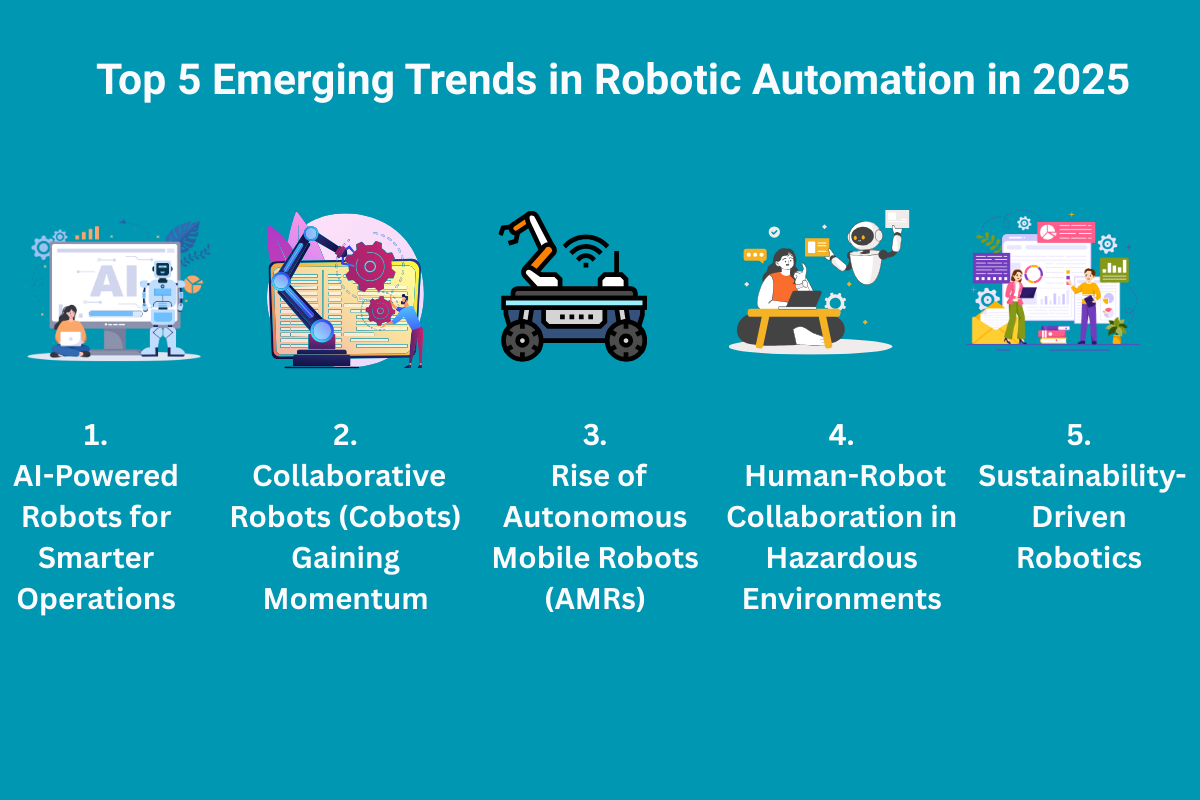

The landscape of robotics is undergoing a rapid transformation, and 2025 is expected to be a turning point for industries adopting advanced automation. What once started as basic robotic arms in assembly lines has now evolved into intelligent, adaptive systems that can collaborate with humans, analyze data, and even operate independently in complex environments. Businesses across manufacturing, logistics, healthcare, retail, and agriculture are increasingly turning to robotic automation, not just for efficiency but also for innovation, safety, and sustainability.

One of the biggest drivers of change is the integration of Artificial Intelligence (AI) into robotics. Smart robots equipped with machine learning algorithms are capable of making data-driven decisions, self-adjusting processes, and predicting failures before they happen. This enables organizations to run operations with greater accuracy and minimal downtime. Alongside this, collaborative robots (cobots) are reshaping the workplace by assisting human workers instead of replacing them. Their ease of programming and adaptability makes them especially valuable for small and medium-sized businesses looking to scale automation without high costs.

In parallel, autonomous mobile robots (AMRs) are redefining supply chain management. With their ability to navigate warehouses, transport goods, and manage inventory autonomously, they are proving to be indispensable in fast-moving industries like e-commerce and logistics. Meanwhile, hazardous industries such as mining and oil & gas are witnessing increased use of robots in dangerous environments, ensuring human safety while maintaining productivity. These robots perform inspections, handle toxic materials, and carry out high-risk tasks with precision.

Another major trend shaping the future is the focus on sustainability-driven robotics. As global industries strive to meet climate goals, robots are being designed to conserve energy, minimize waste, and optimize the use of natural resources. From precision farming robots that reduce pesticide use to energy-efficient machines in factories, robotics is emerging as a key enabler of sustainable operations.

In essence, the trends in 2025 highlight a shift from traditional robotic automation to a more intelligent, collaborative, and eco-conscious ecosystem. Companies that embrace these innovations are not only securing a competitive edge but also contributing to safer workplaces and a more sustainable future.

The year 2025 is shaping up to be a milestone for robotic automation, with industries across the globe accelerating adoption to improve efficiency, safety, and scalability. As automation continues to evolve beyond simple repetitive tasks, businesses are embracing advanced robotics integrated with cutting-edge technologies. Below are the five emerging trends that are expected to define robotic automation in 2025.

1. AI-Powered Robots for Smarter Operations

Robots are no longer just about precision and speed—they’re becoming intelligent decision-makers. By integrating Artificial Intelligence (AI) and Machine Learning (ML), modern robots can learn from real-time data, predict outcomes, and optimize processes without constant human intervention. For instance, predictive maintenance powered by AI ensures machines operate with minimal downtime, saving both time and cost.

2. Collaborative Robots (Cobots) Gaining Momentum

Cobots, designed to work safely alongside humans, are increasingly being adopted in manufacturing, logistics, and healthcare. Unlike traditional industrial robots, cobots are flexible, user-friendly, and adaptable for small and medium enterprises (SMEs). In 2025, expect more cobots handling complex assembly lines, assisting in surgical procedures, and even supporting last-mile delivery.

3. Rise of Autonomous Mobile Robots (AMRs)

With supply chains becoming more dynamic, the demand for autonomous mobile robots is surging. AMRs navigate warehouses, factories, and retail floors independently using advanced sensors, LiDAR, and computer vision. In 2025, these robots will play a critical role in logistics, managing inventory, transporting goods, and streamlining order fulfillment with minimal errors.

4. Human-Robot Collaboration in Hazardous Environments

Safety remains a top priority in industries such as mining, oil & gas, and construction. Robots are now being deployed in hazardous environments where human exposure is risky. From inspection drones to robotic arms handling toxic substances, this trend ensures higher safety while maintaining productivity. By 2025, the synergy between humans and robots in dangerous workplaces will significantly reduce accidents.

5. Sustainability-Driven Robotics

As businesses push for greener operations, robotics is playing a vital role in driving sustainability. Energy-efficient robots, recycling-focused automation systems, and precision-driven agricultural robots are contributing to reduced waste and optimized resource utilization. In 2025, sustainable robotics will help industries align with global environmental goals while reducing operational costs.

Final Thoughts

The future of robotic automation is not about replacing humans—it’s about enhancing capabilities, improving safety, and enabling businesses to adapt quickly to market demands. Companies that embrace these emerging trends in 2025 will not only stay ahead of the competition but also set new standards for innovation and growth.

ISO 27001

Posted at 10:04h, 25 AugustI appreciate how you address the systemic aspects of topic. Too many discussions focus on individual tactics without considering the broader system dynamics you highlight here.

Best resort in Cebu

Posted at 11:47h, 25 AugustYour blog has become my daily dose of positivity and inspiration It’s a space that I always look forward to visiting